All About Oil Field Equipment and Pipeline Equipment: Key Insights and Important Details

Oil field equipment and pipeline systems play a pivotal duty in the oil and gas sector. They are necessary for the reliable removal and transportation of hydrocarbons. Key elements, such as drilling rigs and storage space tanks, straight influence functional success. Developments in technology guarantee to enhance safety and effectiveness. Understanding these elements is vital for anybody associated with or curious about this complicated sector, as it establishes the phase for much deeper exploration of industry methods.

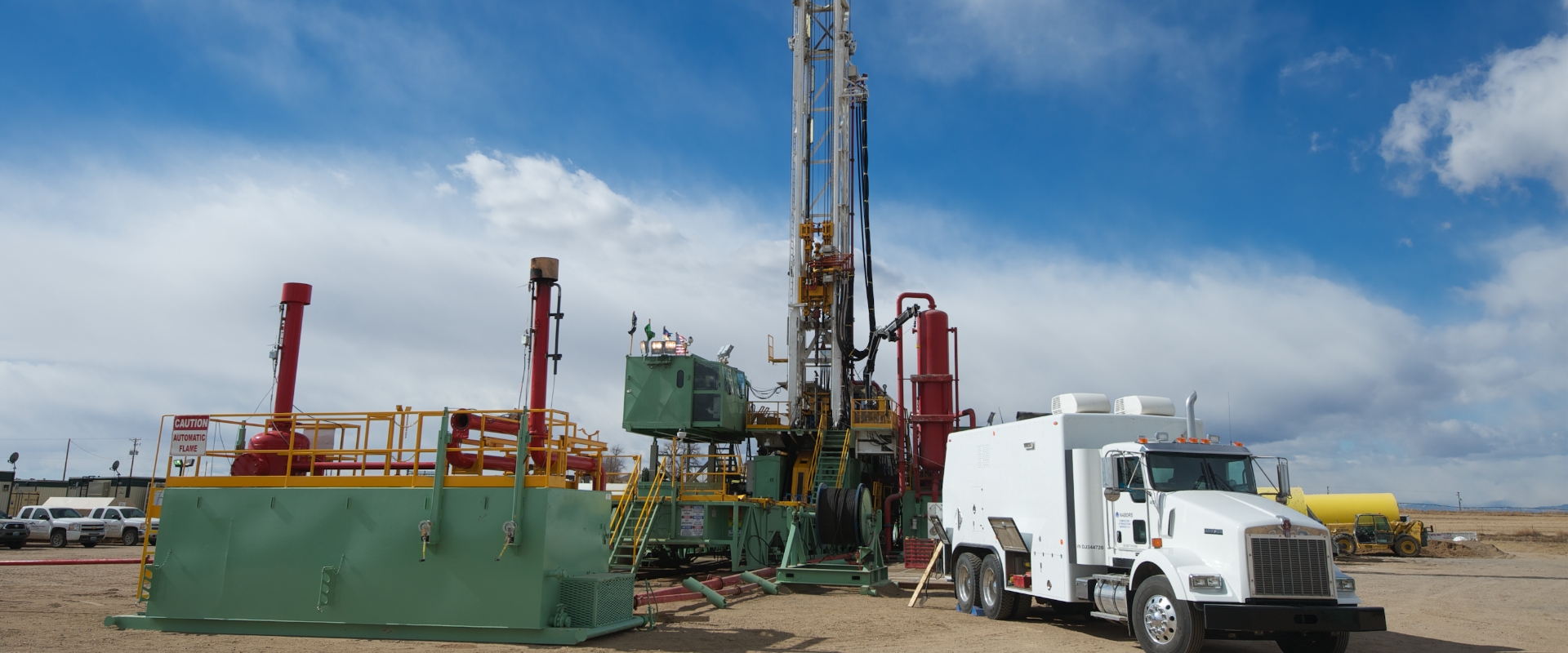

Summary of Oil Field Equipment

As the demand for oil remains to expand, understanding the equipment used in oil areas ends up being significantly essential. Oil field equipment encompasses a large range of machinery and devices vital for exploration, removal, and processing. Secret elements include drilling rigs, which are essential for getting to oil reservoirs, and production tools, such as separators and pumps, that promote the extraction process. Superior Rentals midland. Furthermore, tank play a significant function in holding crude oil prior to transport. Security equipment, consisting of blowout preventers and pressure determines, assures functional security and efficiency. Each tool functions cohesively to maximize manufacturing and keep reliable workflow. Experience with this tools is necessary for professionals in the market to ensure effective operations and adherence to security criteria

Kinds Of Drilling Rigs and Their Applications

Drilling rigs offer as the foundation of oil removal procedures, with numerous types created for details geological problems and functional needs. The most common kinds include rotary boring rigs, which utilize a rotating drill little bit to pass through the planet, and cable tool rigs, known for their percussion boring technique. For overseas operations, jack-up rigs and semi-submersible rigs offer security and assistance in marine settings. In addition, directional exploration rigs allow drivers to drill at angles, getting to down payments that are not vertically obtainable. Each rig type has distinct advantages, enhancing efficiency and safety and security based upon the drilling environment. Picking the proper gear is essential for taking full advantage of resource extraction while reducing environmental impact and functional prices.

Important Pipeline Equipment and Their Functions

Pipeline facilities is necessary for the transport of oil and gas from extraction websites to processing facilities and end-users. Different important equipment elements facilitate this process. Pipelines themselves function as the main conduits, made to endure high pressure and destructive substances. Pump terminals are vital for preserving circulation by improving pressure along the pipeline. Valves play a vital role in controlling flow and isolating sections for upkeep. Furthermore, fittings and adapters ensure safe and secure joints in between pipe sections. Monitoring systems, consisting of circulation meters and stress sensing units, are essential for spotting leaks and optimizing circulation rates. Pigging equipment is utilized for upkeep and cleaning, securing pipeline honesty and effectiveness. With each other, these parts form the backbone of a reliable pipeline system.

Advancements and Technologies in Oil and Gas Equipment

Safety And Security and Maintenance Practices in the Oil Sector

While the oil industry has actually made substantial strides in modern technology and efficiency, the relevance of robust security and upkeep practices can not be overemphasized. Reliable safety and security protocols are important to shield workers and the atmosphere, reducing the danger of crashes and spills. Normal evaluations and maintenance of tools aid determine possible concerns before they rise, making sure operational stability. Educating programs for employees are crucial, emphasizing the significance of security recognition and emergency feedback procedures. Additionally, adherence to market policies and standards cultivates a society of safety. Carrying out sophisticated tracking technologies can additionally improve maintenance practices, allowing for real-time evaluations of tools problems. Eventually, prioritizing safety and upkeep is essential to the sustainability and success of the oil industry.

Regularly Asked Inquiries

What Are the Ecological Impacts of Oil Field Equipment?

The environmental impacts of oil outdoor gas line field equipment consist of environment damage, water contamination, and air pollution (Superior Rentals fusion machines). Additionally, tools malfunction can lead to spills, detrimentally impacting wildlife and communities, highlighting the need for stringent guidelines and tracking

Just How Is Oil Field Equipment Delivered to Remote Locations?

Moving oil field equipment to remote places often entails specific lorries, helicopters, or barges. Logistics firms coordinate routes, making certain devices shows up safely and successfully, considering terrain and ease of access to minimize delays and optimize performance.

What Regulatory Standards Govern Oil Field Equipment?

Governing standards governing oil field equipment mainly include security, environmental management, and operational effectiveness standards. Agencies such as OSHA and EPA apply these replacing plumbing in concrete slab policies to ensure safe practices and lessen ecological impact in oil extraction operations.

What Skills Are Required to Operate Oil Field Equipment?

How Do Oil Costs Affect Equipment Need and Use?

Oil prices greatly influence tools need and usage. Higher rates generally lead to boosted exploration and manufacturing tasks, driving demand for equipment. On the other hand, reduced rates might result in minimized procedures and lowered need for devices.